This article was originally published by UVic News on June 22, 2021.

Incorporating an industrial by-product into lithium-sulphur batteries may enable the creation of smaller, safer and cheaper electric vehicle (EV) batteries with doubled energy capacity, according to researchers leading a new Pacific Institute for Climate Solutions (PICS) research partnership.

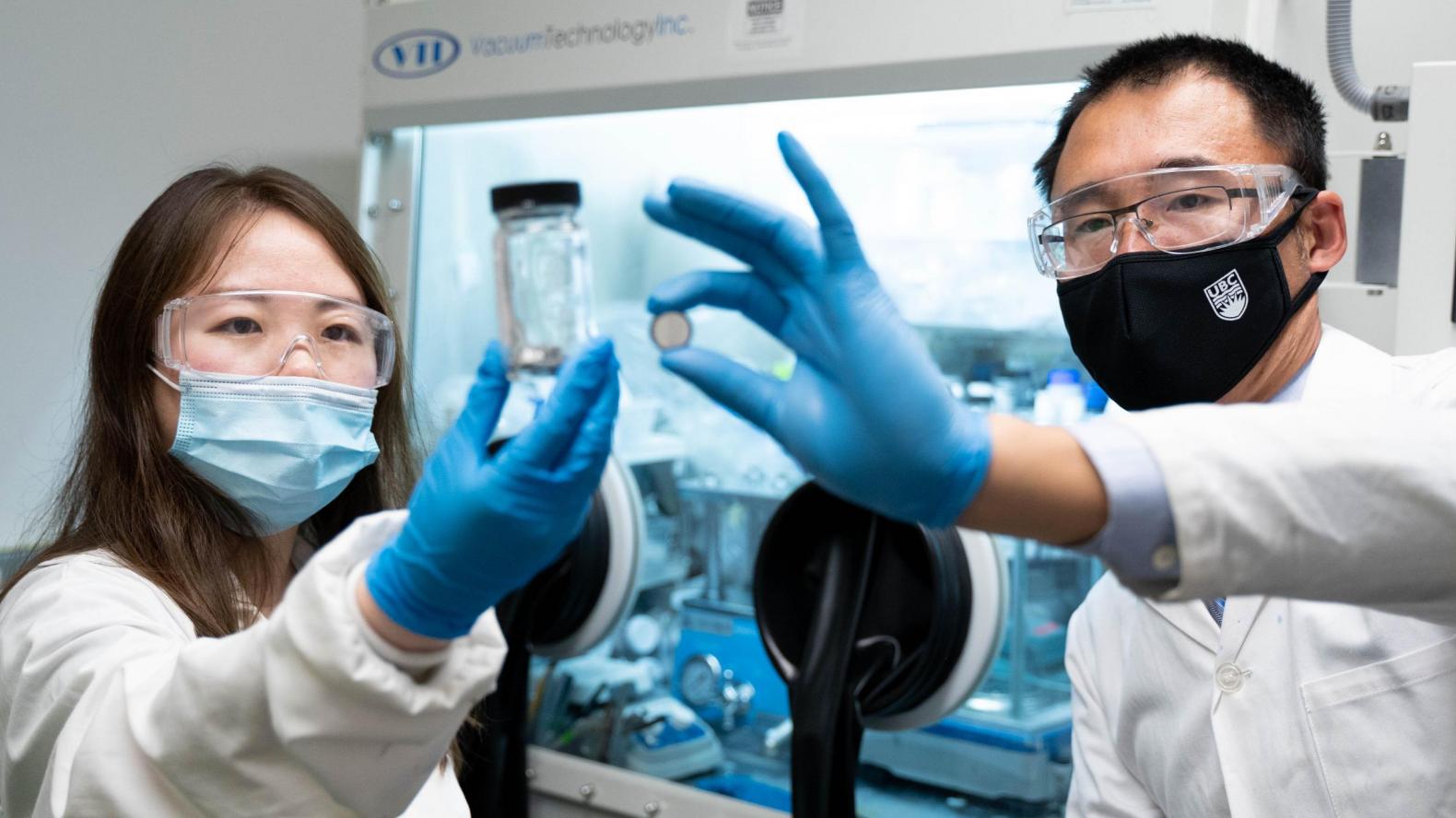

Tellurium Boosted Li-S Batteries for Zero-Emission Vehicles is a $180,000, three-year PICS project led by the University of British Columbia (UBC) in partnership with University of Victoria hosted and led PICS, and funded by the Government of British Columbia’s CleanBC Go Electric program through the Ministry of Energy, Mines and Low Carbon Innovation.

The project is investigating the feasibility of incorporating tellurium (Te)—an industrial by-product of the copper and lead-zinc smelting processing—into solid state lithium-sulphur batteries.

Project principal investigator and UBC Okanagan assistant professor, Jian Liu, says tellurium’s high electrical conductivity and high volumetric properties could enable greater energy storage and faster charging and discharging than conventional EV lithium-ion batteries. He says this ultimately means extended EV range and convenience for drivers.

“People have been looking into sulphur batteries for many years, but it is challenging to commercialize because sulphur doesn’t transport electrons at all,” he says. “We are looking for a way to balance electronic conductivity with energy density as a way to make lithium-sulphur batteries viable.”

Liu says significant limitations exist, including tellurium’s tendency to expand and contract but the researchers believe that problem can be overcome by creating a stable compound within the battery. Furthermore, solid state tellurium-based batteries could be safer than conventional lithium-ion batteries, which employ flammable liquid electrolytes.

With the goal of creating a sustainable battery industry, the intent is to repurpose industrial waste into high-value products, and to also recover and reuse tellurium from end-of-service tellurium batteries.

PICS Associate Director Bentley Allan says, if technologically successful, this project will accelerate transportation electrification and the shift to decarbonized energy.

“Extending the range and safety of zero-emission vehicles (ZEVs) would help accelerate adoption rates around the world, and support progress towards a sustainable circular economy through raw material recycling,” he says. “In addition, the kind of industry partnerships at the heart of this project are essential to building green industry here in British Columbia.”

“With the highest uptake rates of electric vehicles in North America, and a number of local companies across the EV supply chain, BC is positioned to become a leader in the industry,” says Bruce Ralston, minister of Energy, Mines and Low Carbon Innovation. “That’s why we’re supporting innovative new ZEV technologies that could potentially put by-products of BC minerals and metals to good use, helping us transition to a low carbon economy and play a significant role in Canada’s development of a national EV battery supply chain.”

This UBC-led PICS project is supported by the Government of British Columbia, GLABAT Solid-State Battery Inc., Fenix Advanced Materials, Nature Sciences and Engineering Research Council of Canada, National Research Council, Canada Foundation for Innovation, BC Knowledge Development Fund and Mitacs Accelerate Program.

The Pacific Institute for Climate Solutions develops impactful, evidence-based climate change solutions through collaborative partnerships that connect solution seekers with experts from BC’s four leading research universities. PICS is hosted and led by UVic in collaboration with the University of British Columbia, Simon Fraser University and the University of Northern British Columbia.